Make roads last longer and tax dollars go further.

Slurry Pavers was founded in 1966 as one of the original Pavement Preservation companies in the United States. As a pioneer in sustainable pavement, SPI has played a significant role in product, staff, equipment and process development for the Pavement Preservation industry. Over the years, we’ve increased our ability to help customers by expanding our pavement preservation and maintenance services adding structural repair, asphalt emulsion products, pavement reclamation and recycling, soil stabilization and commercial services. Through it all, we’ve been committed to the safety of our staff and the traveling public as we’ve delivered the best possible options and outcomes for our customers.

Protecting what we've paid for just makes sense.

Whether staining a deck, painting our house, or sealing our own asphalt driveway, the benefits of protecting our personal investments is obvious. So what about the infrastructure our tax dollars pay for? The American Society of Civil Engineers rated America's roads a "D" in their latest Annual Report Card on America's Infrastructure. If anything is clear from reading the report, it's that continuing to build and maintain our road networks using traditional methods and a "worst first" approach will not fix the problem. However, there is an ever-growing body of evidence that shows tremendous gains can be made on road network health when pavement preservation is used consistently. The reason for this is two-fold. First, pavement preservation extends the life of individual asphalt roads at rates that outweigh the expense. Second, the annual savings and life extension benefits combine to allow for more roads to be addressed over time utilizing the same budget. The result is an overall improved network without any increase in cost. That's the heart and goal of pavement preservation and recycling.

You can learn more about what we do, why we do it, and how we're helping to raise the grade in

the video here.

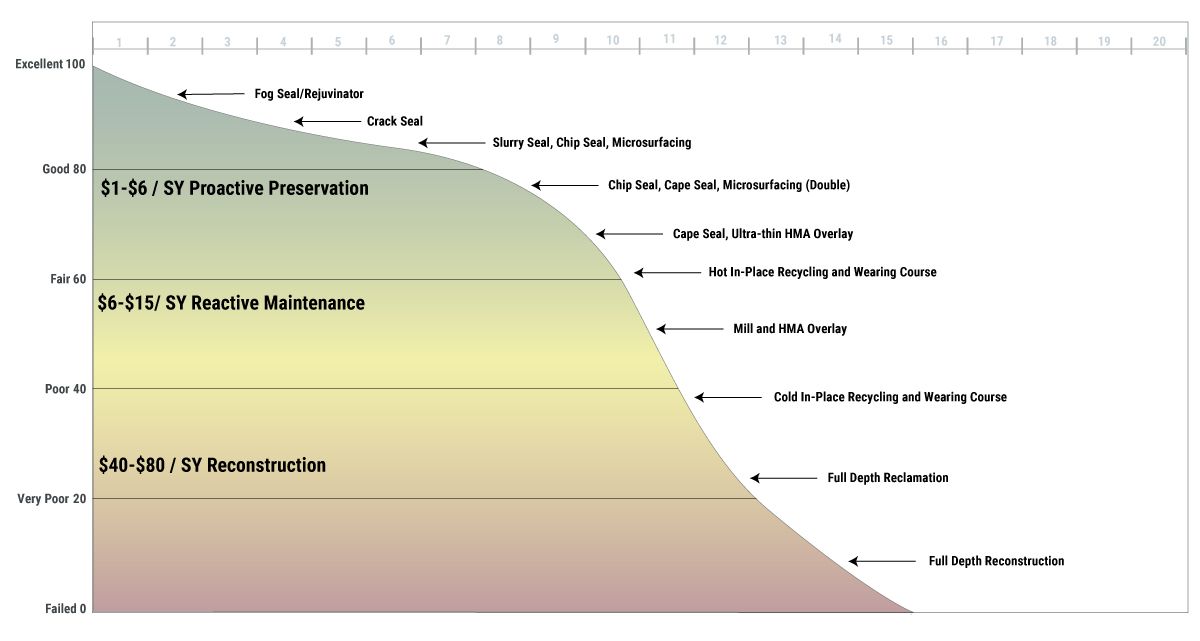

Please note that any costs mentioned in the video or the graphics below are based on national averages and may not reflect the current costs in your area.

The right treatment, on the right road, at the right time, makes all the difference.

Today, there are many options road administrators can employ to optimize network management. The chart illustrates the deterioration curve of an asphalt road and the wide spectrum of choices administrators now have to apply the right treatment, on the right road, at the right time.

As the chart shows, using preservation before roads deteriorate saves money in the immediate. The savings enables more roads that are further down the deterioration curve to be addressed at the higher costs necessary to address their condition. The treated roads also add value by pushing out the deterioration curve and future maintenance costs while keeping them healthier, safer and more enjoyable for longer.

While we don't offer all of the options illustrated, we do provide an array of key services to sustainably help build and maintain asphalt pavements. These include:

fog seal,

crack seal,

slurry seal,

chip seal,

cape seal,

micro surfacing, and

full depth reclamation. We also support the efforts of our allies in the plant mix asphalt industry with

milling,

soil stabilization and

striping

services. We also help

commercial

interests maintain their pavements more sustainably with a wide variety of products and services specific to their needs.

An optimized maintenance strategy improves network sustainability.

Compared to a "worst first" approach to pavement maintenance, a modern pavement preservation strategy can pay tremendous dividends. In this example, incorporating pavement preservation allows this network to be maintained in an overall better condition while realizing tremendous cost savings.

You can explore how to optimize pavement management using calculators provided by the Pavement Preservation and Recycling Alliance. Registered users can confidentially input their own costs, PCI values and other data to make the results relevant to their specific situation. Calculator options include:

Life Cycle Cost Calculator: Compare long-term strategies to see real world costs and optimized savings.

Equivalent Annualized Cost Calculator: Find your true costs by comparing expense vs. life extension.

Remaining Service Life Calculator: See how many extra years an optimized strategy gives your network.

Cost-Benefit-Value Calculator: Learn how to best prioritize roads in your network by discovering what options can deliver the most value.

Another helpful tool is the pamphlet "A Quick Check on Your Network Health" published by the Federal Highway Administration and the National Center for Pavement Preservation. This provides an explanation and insights into "Remaining Service Life" and includes a Pavement Network Evaluation Worksheet.

You can learn more about pavement preservation and cutting edge asphalt technologies found in the extensive research published by the National Center for Asphalt Technology at Auburn University. You can also learn how state and local road administrators have improved their networks with pavement preservation and recycling in the "How I Built This Network" webinars found on roadresource.org.

Our Family of Companies

We couldn't help customers or support our mission nearly as well without the partnership of our subsidiaries.

Asphalt Emulsion Industries

Asphalt Emulsion Industries produces quality emulsion products for contractors and DOTs throughout the Mid-Atlantic and Southeast. AEI's AMRL accredited lab provides testing, mix design and quality control services. The lab is accredited in Maryland, North Carolina and Virginia. Materials are approved for use in Delaware, Maryland, North Carolina, South Carolina, Tennessee, Virginia and West Virginia.

Click to visit the AEI website.

Whitehurst Transport

Whitehurst Transport specializes in the safe and efficient movement of Asphalt Emulsions & Cutbacks, Asphalt Flux Distillate, Fuel Oils, Liquid Asphalt, Cement, Oily Waste Water, Recycled Oil, and Residual Fuel Oils with operations spanning the East Coast from New Jersey to South Carolina.

Click to visit the Whitehurst Transport website.

Our Best Known Services

Several key services help our customers sustainably manage their networks.